Architecture is one of the few industries still treating every project like a one-off. While product designers iterate, architects often reinvent. The result? Cost overruns, delays, inefficiencies and a user experience that doesn’t always deliver.

In product design, the process is as important as the outcome. Iteration is everything. The best products aren’t one-offs; they’re continuously refined through prototyping, user feedback, and testing. Each cycle eliminates flaws, improves usability, and delivers a better human experience.

Think about how each iPhone iteration is slightly better than the last. This isn’t just a creative process. It’s how to reduce risk and build more successful products.

This mindset opens new possibilities for designing and delivering the built environment, using what’s known as a kit-of-parts (KOP) approach.

From bespoke to repeatable.

Many building projects are still treated as bespoke, standalone efforts. The impact? Predictable and persistent challenges:

- Cost overruns: Over 90% of construction projects experience cost overruns and delays due to inefficiencies in planning and delivery.

- Massive Rework Costs: Errors and rework cost the UK construction industry up to £23 billion annually, around 3.6% of GDP.

- Waste Generation: Construction generates 60% of the UK’s waste, 13% of raw materials being discarded unused.

- Safety Concerns: Construction accounts for 30% of workplace fatalities.

Governments are taking notice. The UK’s Platform Design Programme and the modular housing pilots in NSW, Australia are part of a shift toward system-based, scalable construction.

Kit-of-Parts: Product thinking in architectural design

The kit-of-parts (KOP) approach breaks down the design into modular components that can be combined and adapted.

It’s not about identical buildings. It’s about smart systems: Each part is designed to interface structurally, visually, and functionally with others. These might include walls, lighting, furniture, or even entire utility systems, each designed for consistency, clarity, and ease of integration.

By shifting from bespoke to modular, teams reduce complexity and enable faster, more consistent delivery.

Standardisation brings real benefits:

- Faster build times - prefabricated and modular systems can cut schedules by 20–50%. (McKinsey, 2017).

- Greater cost predictability - integrating standardised processes and unified information systems can reduce design costs by 15–20% and construction costs by approximately 10%. (Deloitte, 2020)

- Reducing material waste by up to 90%. (WRAP UK)

- Higher performance - repeatable systems support consistent quality and simplify compliance.

- Most importantly, this approach frees up time and effort to focus on what truly matters, the experience of the people using the space.

Designing for people, not just places

In product design, user experience is central. Concepts are tested and refined to be intuitive, useful, and invisible in the best way.

As Don Norman writes in The Design of Everyday Things:

“Good design fits our needs so well that the design is invisible.”

Architecture can and should follow the same principle. Wayfinding, circulation, entrances, and spatial flow should feel effortless. When these elements are designed, tested, and refined before construction, buildings become more intuitive and human.

Circular economy: Closing the loop

Most buildings aren’t built for change or end of life, yet they’re often refurbished every 5–7 years. And in Australia, construction and demolition generate 45% of total waste.

Good product design plans for the full lifecycle. It designs for disassembly, reuse, and adaptability.

A kit-of-parts enables the same in architecture. Components like walls, ceilings, and finishes can be reconfigured or reused without demolition, reducing waste and extending a building’s life.

Take Fastmount’s hidden clip system: it lets interior panels be removed and reinstalled without damage. No adhesives, no landfill.

This is how buildings become material banks, not waste streams.

Designing infrastructure like a product

Maynard’s work on the Elizabeth Line is a prime example of product thinking at scale.

Instead of designing each station in isolation, the focus was on the entire user journey. A kit-of-parts was developed to bring clarity, consistency, and ease of use across the network, including lighting, signage and furniture.

Cladding types were reduced from 80 to just 9 - simplifying manufacturing, logistics, and installation.

The result was not only more efficient, it created a consistent, intuitive, and familiar experience across the line. This wasn’t just efficient. It was user centred.

A case study in scalable design: The Forge

The results were measurable:

- 13% faster construction

- 9.5% lower capital costs

- 50% reduction in on-site labour

- 40% less steel used

- 24% reduction in embodied carbon

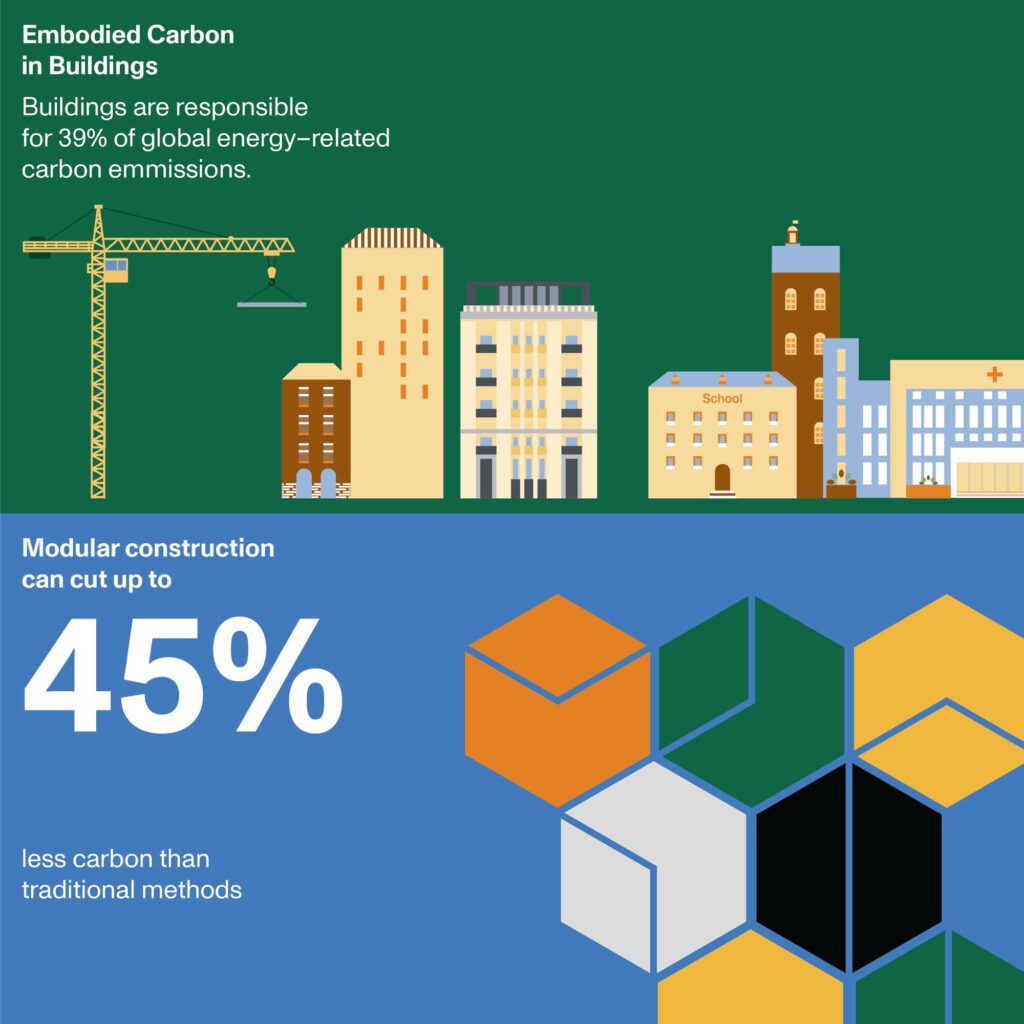

The Forge wasn’t just efficient, it set a new standard for scalable, low-carbon design. With buildings accounting for 39% of global carbon emissions (11% from materials and construction), its modular approach showed how smarter manufacturing and reduced waste can cut embodied carbon. Its success helped prompt the UK government's support for platform-based construction in future infrastructure.

Scalable, repeatable, human-centered

Scalable design approaches don’t mean replicating identical buildings. It’s about solving repeatable problems with systems. Applied intelligently, in context.

A Kit-of-parts allows the focus on what matters most: People, Place and Product. It reduces unnecessary variation and cost, while enabling each project to become the best iteration of the product.

This is how we create designs that evolve, improve, and scale.

What if your next project was less prototype and more product? Get in touch with us to find out how we can help with your latest project.

Words by Charles Parford-Plant, Senior Industrial Designer.